PRODUCT

ROPROQ's modular architecture eases complexity and enables integration of precisely the modules needed to solve challenges

Data prep & forecasting module automatically cleans and enriches raw transaction data, verifies accuracy, and filters out one-off events to reveal true demand.

It models lookalike goods, inter-item substitution, seasonality (including “floating” events like weather or pandemics), weekly cycles (or intra-day statistic for fresh items), and promotional uplifts.

For new or low-volume SKUs, it inherits parameters from similar items to generate reliable forecasts - delivering high-precision, ready-to-use demand projections.

Optimization module finds the most profitable inventory control strategy – daily – for every SKU at each network location.

Financial model: uses a robust, end-to-end model of all variable costs – holding, ordering, and stock-out losses – to maximize net profit.

Product-mix assessment: automatically classifies SKUs by data quality and profitability (e.g., active, cross-dock, or low-data items) and flags unprofitable lines.

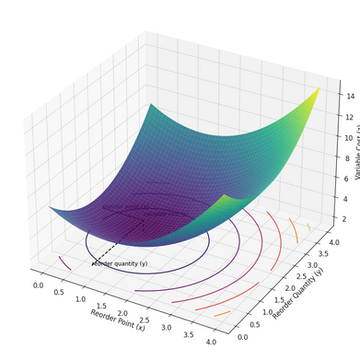

Optimization engine: determines the optimal reorder point (ROP) and reorder quantity (ROQ) for each item by analyzing holding costs, replenishment costs, and shortage costs to minimize total variable costs.

Resource constraints: accounts for real-world limits – warehouse capacity, working-capital availability and limits, supply chain throughput, and any combination of constraints – ensuring the recommended strategy is fully implementable.

Together, these capabilities deliver a daily, SKU-level roadmap for profit-driven replenishment.

Replenishment automation module transforms optimized inventory parameters into seamless, hands-off ordering and execution:

-

Automated order generation - Each day, the system converts SKU-level reorder points and quantities into purchase orders, transfer requests, or production replenishment orders – ready for approval or direct submission.

-

Workflow orchestration - Configurable approval chains and exception rules ensure the right stakeholders review and sign off only on exceptions, while routine orders flow automatically.

-

Real-time dashboards & alerts - Intuitive dashboards display upcoming orders, fill-rate projections, and exception flags (e.g., low supplier stock, capacity limits), with email or in-app notifications to keep teams informed.

-

ERP and system integration - Out-of-the-box connectors and open APIs link directly to any ERP, WMS, or procurement platform – syncing master data, stock levels, and orders in real time.

-

Continuous feedback loop - Execution data (e.g., supplier lead times, order fulfilment rates) feeds back into forecasting and optimization, ensuring the next cycle is even more accurate.

By automating the entire replenishment process – from optimized plan to executed order – ROPROQ frees teams from manual tasks, reduces errors, and ensures inventory levels are always aligned with business needs.

-

Perishables optimization module brings specialized intelligence to short‐shelf‐life items, ensuring freshness, minimizing waste, and maximizing sales:

-

Shelf-life-aware forecasting - Incorporates per-SKU sell-by windows, decay curves, and temperature-sensitive spoilage rates into demand projections – so forecasts reflect true sales potential over each item’s usable life.

-

Dynamic replenishment parameters - Calculates optimal order quantities and reorder points that balance freshness, service levels, and waste costs – adjusting daily to account for on-hand age profiles and upcoming deliveries.

-

Automatic markdown recommendations - Triggers price-reduction alerts as products approach key “sell-before” thresholds, with suggested markdown levels based on remaining shelf life, demand sensitivity, and margin targets.

-

Lot-level inventory rotation (FEFO) - Generates pick-and-ship directives that always pull the earliest-expiring items first, ensuring no product is left to spoil while newer stock circulates.

-

Real-time monitoring & alerts - Tracks in-store and back-room inventory age profiles, flagging high-risk batches, temperature deviations, or unexpected slow-moves for immediate action.

By marrying shelf-life dynamics with AI-driven forecasting and profit-centric replenishment, the perishables module helps retailers keep fresh goods fresh – boosting sales, slashing waste, and delighting customers.

-

Elastic demand module quantifies how pricing, promotions, and market factors influence SKU-level demand, enabling revenue- and margin-driven decisions:

-

Price-elasticity estimation - Analyzes historical price changes and sales volumes to calculate how sensitive each SKU’s demand is to price movements, or establish and monitor price-testing sites.

-

Promotion-response modelling - Learns uplift patterns from past campaigns (discounts, BOGOs, coupons) to predict incremental sales and cannibalization effects.

-

Cross-SKU substitution - Identifies how demand shifts between related products when one SKU’s price or availability changes – ensuring portfolio-wide optimization.

-

Scenario simulation - Runs “what-if” analyses for price points, promotional depths, and competitive price moves, showing projected sales, revenue, and profit impacts.

-

Integrated optimization - Feeds elasticity insights into replenishment and pricing engines, aligning inventory levels and price strategies to maximize total margin.

By embedding elasticity modeling into forecasting and optimization, ROPROQ empowers retailers and distributors to set prices and promotions that drive profitable demand – and stock accordingly.

-

Dynamic pricing module continuously adjusts prices to balance demand, margin, and inventory objectives in real time:

-

Integrated demand signals - Combines live sales velocity, forecasted demand, and price-elasticity insights to determine optimal price points for each SKU.

-

Competitive benchmarking - Ingests competitor pricing data – online or via partner feeds – to ensure your prices remain attractive without sacrificing profitability.

-

Margin-aware optimization - Uses end-to-end financial models to weigh incremental revenue against cost of goods, holding, and stock-out risks, ensuring each price change contributes to net profit.

-

Rule-based guardrails - Supports custom constraints (minimum/maximum prices, promotional calendars, brand guidelines) to prevent unwanted price swings.

-

Real-time execution - Publishes price updates directly to POS, e-commerce platforms, or digital signage—either instantly or in scheduled windows.

-

Performance monitoring - Dashboards track uplift, margin impact, and inventory turnover, with alerts for any deviation from targets or unexpected market shifts.

By embedding dynamic pricing intelligence into your operations, ROPROQ helps you capture every dollar of value – maximizing margins, clearing inventory, and responding instantly to market changes.

-

Observation Tower module provides a single pane of glass for all sales, orders, and replenishment data – creating a trusted, transaction-level database that underpins deep analytics and live reporting across your entire operation:

-

Unified data repository - Ingests and harmonizes transactional feeds from forecasting, optimization, and replenishment modules into one consistent data store – independent of your ERP, WMS, or upstream systems.

-

Real-time dashboards & KPI tracking - Pre-built dashboards surface key metrics (fill rates, stock turns, working-capital usage) with drill-down from corporate KPIs to individual SKU movements in any location.

-

Ad hoc analytics & self-service BI - Exposes transaction-level detail via SQL, API, or BI connectors so data scientists or power users can run custom queries and build reports without affecting accounting periods or core ERP tables.

-

Agile to change - Because Observation Tower sits on its own data layer, it survives platform migrations, ERP upgrades, mergers & acquisitions, and new system rollouts – preserving historical continuity and avoiding data gaps.

-

One-stop data source - Acts as the canonical “single source of truth” for all sales, orders, and replenishment activity – eliminating fragmented spreadsheets and siloed reports.

By bringing together every forecast, order, and execution record into a single, reliable database, the Observation Tower empowers your teams to monitor performance, troubleshoot issues, and drive continuous improvement – without ever touching your core systems.

-

FEATURES

Our contribution

ROPROQ introduces an economic decision layer to replenishment

By modeling demand and lead times probabilistically and valuing every decision in financial terms, the system automates daily, profit-maximizing replenishment for every SKU and location, fully aligned with real-world constraints and enterprise-scale operations